Biomass converter providing heat and hot water for ABDO College

If you have studied at ABDO College or stayed in the accommodation on site, you may not have thought about where the hot water comes from, nor considered how the mansion house is heated. But did you know that the Godmersham site is home to an innovative biomass converter which uses local wood to heat hot water which is piped across the estate?

The project started in 2013 and installing the vast building, pumps and boilers took a year. Now there are two furnaces which are fed woodchip sources from trees grown on the estate and in other woods within a few miles.

A biomass convertor is a carbon neutral source of energy. It is also truly renewable. At Godmersham most of the wood that is used is chestnut. Estate woodsman Graham explains that chestnut is a fast-growing fuel source. He coppices the woods in rotation, safe in the knowledge that the chestnuts will regrow in 15-25 years, while ash could take 50 years. The natural oils in chestnut also make it good for burning. This is a fuel source that has the potential to far outlast traditional fossil fuels, with only sun and rain needed for maintenance. What’s more, any carbon that is released into the atmosphere from biomass fuels is what was absorbed by the trees during their lifecycles. And as these plants are replenished, the new ones then absorb the same amount of carbon again.

The project was kickstarted with a government grant and has a 20-year contract until 2034. It is not without challenges. Wood is harvested and stored in three-meter length boards. It takes three to four years for the wood to dry and be ready for chipping and burning. If you drive into Godmersham from the Ashford direction you may have noticed the vast piles of wood which are stacked to dry. The furnaces consume 12,000 tonnes of wood per year and there are two woodsmen on the estate responsible for coppicing and chipping as well as daily visits to the boiler room.

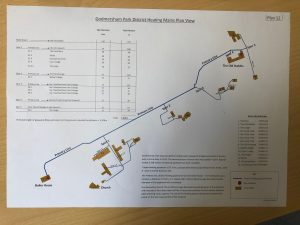

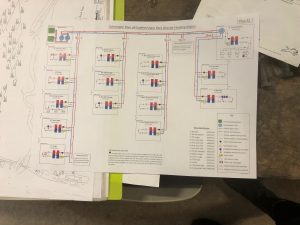

The powerful pumps on the site circulate 32 tonnes of water at 80 degrees across 3.5 miles of pipes reaching almost all the tenants’ buildings. The water really only loses two degrees from the boiler room to the mansion where it provides all the heating and hot water.

A computer within the boiler room controls the way the furnaces burn so the process is as clean as it can be. It monitors to see if wood is dry enough – about 20 per cent moisture is ideal, and the woodchips need to be around 30mm in size. There are two furnaces so there is always a backup – and in winter both can be in action at the same time. The ash which is created as waste is mixed in with dung and returned to the fields as fertilizer.

ABDO College’s buildings administrator Justin Hall has seen the benefits to students since the system was installed. He says, “Our accommodation used to be heated by night storage heaters which warmed the building well in the morning but needed to be boosted in the evenings. We switched systems in 2015. Now the wet radiator system which is controllable and ensures the accommodation is warm when the students need it to be. And the mansion has a ready supply of heat and hot water.”

So, next time you turn on a tap at ABDO College, or brush past a warm radiator, you will know that all the heat comes from a carbon neutral and renewable source, produced locally.